I felt that this chapter needed more color pictures, so I added some recent and informative picture-stories to help round out this chapter where some pictures are a few years old.

Value of the Duck-Under

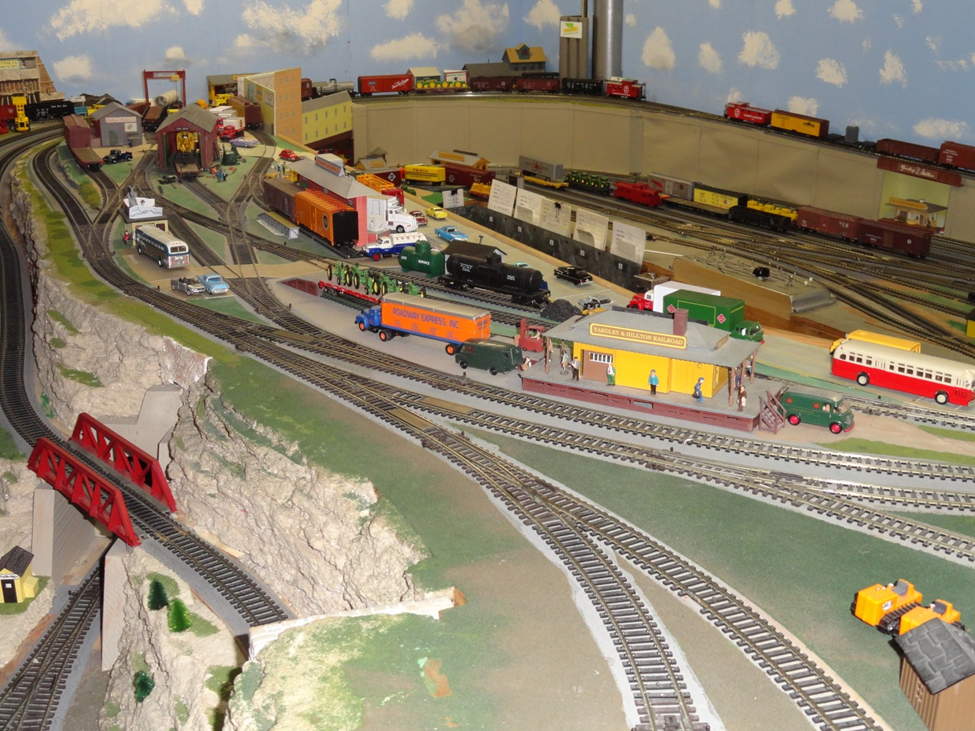

I realize that not everyone wants a duck-under layout but here is why I like mine. This picture was taken by standing on a step-ladder with the camera held high overhead so we can see the operation pit and classification yard at Yardley (without the coal dock and water tower), some car forwarding cards in pockets to the left of the Yardley turnout control panel, and a hand held throttle hanging on a screw head on the fascia, all of the 2×6 foot operation pit and the middle part of Hillton in the foreground. The classification yard can be operated while seated on a stool. These are the things that make the duck-under worth doing.

This view shows the classification yard and its very workable facilities, sometimes difficult to find in a model layout. The strong features are its location inside the mainline loop and ready access to the hidden staging yard, so classification operations never interferes with main line running trains. Within the yard is a full train length runaround to put a road engine on either end of a train without fouling the mainline, and a handy little caboose runaround to get the engine on the other end of a car. The industries at Hillton seen in the near foreground can be worked from both inside or outside of the pit.

Yard Master’s View

This is a picture of what the yard master would see (with the coal dock and water tower removed) of the classification yard from his tower. My camera location gives us a birds-eye view about 60 scale feet above the throat tracks. To get this shot I tied the camera onto a flatcar with rubber bands, and placed the car on the Hillton big bridge just outside the Wherezatgo tunnel. It is an interesting view of the Yardley facilities from a different angle. The distance from the camera to the far clouds backdrop is about 10 feet.

There is a lot here to see; from the left are Holden stage pocketed car cards with Hillton above, Holden panel and tall building flats, and a glimpse of Hillton Junction above. In the distance is Yardley freight station at the far end of the yard. Along the right edge is mainline incline to Hillton Junction and the tracks of mainline and passing siding with a crossover to the yard.

Looking West

Modern railroading communications by the train crew to the dispatcher is done with radio. That is a lot different than years ago when such communication was done with a telephone along the weed and briar strewn edge of the mainline with a telephone in a box on a post with a wasp nest inside!

This is a distant view looking westward of most all the layout from as high as I could hold the camera above the Edgeport John Deere dealer. Most of Hillton is shown on the right. To the left is the yard and the operating pit. There are other pictures that have the camera at the opposite end of the room. (Yard Masters View) and (atop Hillton Engine House).

The blue sky backdrop is the backside of left over plywood paneling about 1 1/2 feet tall resting on the layout frame against the room walls. I feel the color is true because on a bright clear summer day I took some blue color samples from the hardware store outside to compare which was best match against the sky then had a quart mixed, the white clouds were done with a small sponge. At the same time I painted a small piece about a foot square to use as a portable sky back drop for use by the photographer.

Atop of Hillton Engine House

The photographer stood on the roof-top of the engine house at Hillton to get this shot of the east end of town. If he would turn 90 degrees right he could get “Switching Ramswell Bulldozer Factory”. The short branch from Hillton Junction ends just at the Greyhound Bus station. In the distance we see that a freight train has just passed another at the Junction pass and is heading down the mainline. Below is a few cars in the yard at Yardley and some car cards pocketed on the edge fascia left of the yard turnout control panel.

Flea markets sometimes are a good source of unusual things that support my layout scenes like the older version of Roadway Trucking Co. paint scheme, the Railway Express trucks, and a City bus. It takes time (years?) to gather bits of meaningful scenery details. Dressing the layout can offer long term enjoyment and you get to run trains during the process.

Switching the Bulldozer Factory

This photo was taken from atop the Hillton Engine house. If the photographer turns left 90 degrees he can get the scene “Atop Hillton Engine House” shown elsewhere.

The Hillton switcher is pulling a loaded flat car out of Ramswell Bulldozer Factory. It is an Athearn heavy duty 4 truck car that was prone to derailments. That was fixed with 6 wheel Buckeye trucks with a Kadee coupler box on top and no span bolster. The Hillton switch crew takes a caboose along in bad weather for a bit of warmth and comfort.

The junk yard now has a scrapped Conrail caboose that serves as a larger office. Scrap yards can handle colorful and interesting gondola loads. In the distance we see the Wherezatgo Tunnel at the end of Hillton’s long bridge and some buildings of the west end of Hillton. I have always liked the way the Bulldozer Factory’s spur track cuts across the wye connector track and another industry spur. The caboose is by Marx with custom decals. The loco is a Varney cast metal cover on a Lifelike drive and has hand applied individual letter decals on a red decal stripe.

The brakeman’s job has its tough spots like squatting down to couple air brake hoses, or climbing upon cars to knock off brakes, or to set brakes and sometimes long walks often on unstable footing through the weeds. It is a job in all kinds of weather that calls for gloves and heavy shoes and a physic that can carry an air brake hose and the wrench to change it or a coupler knuckle a mile!

Yardley Engine servicing facilities

The photographer got some action shots while steam was still in operation. Here we see a couple steamers on the turn table approach tracks at the Yardley engine facility.

Activity at Yardley engine service facilities

The coal dock (with light coal dust weathering) and water tower are kit built plastic as is the engine hostler’s office in the foreground with the train crewmen in discussion. The remote controlled turntable with automatic bridge track polarity is scratch built. All the locomotives and cabooses seen in this shot have been modified in both appearance and performance.

The thing I find amazing is the volume of water these steam locos could consume in a couple hours of heavy work. Those 20,000 gallons is more water than is in your neighbors’ swimming pool. Frequently they needed water in little more than 50 miles. Some tenders were equipped with a scoop to be lowered onto a pan of water between the rails to take water on the fly. Out west where good water was scarce, water tanks, a drilled well and a windmill would be used. Sometimes the water was laden with minerals that would scale-up a boiler or cause foaming unless treated with counter acting chemicals. Steam locomotives required special oils to with-stand the high temperatures of steam cylinders or the wax-like heavy lubricants for mechanical linkages. Good coal that burns without clinkers was a requirement and that stuff is heavy and hard to handle. Out west where coal was thousands of miles away, the railroads used oil to fire their engines.

Into The Roundhouse

Locomotives were almost always headed into the round house because there was more elbow-room there and the front end of the locos is where most of the adjustment and maintenance work was required. This scene has the Engine Hostler’s Office (with the building and train crewmen glued to a clear plastic sheet) relocated to near the caboose track. That provides the ability for the building to be turned around or moved occasionally (for the photographer) and the train crew goes with it.

The steam locomotive became a wonderfully self-regenerating machine as development advanced. Heat rises. The layout of our boiler with long tubes for smoke and heat surrounded by water required a forced draft to burn. The steam after being used for propulsion in the cylinders was exhausted up the smoke stack to help create more draft (chuff chuff) for the fire to burn more vigorously. Steam was used for everything including improving draft when not working to keep the fire burning, a generator for lights, it drove air pumps for brakes and water pumps for new water to the boiler. Steam was used by the injector to put water into the boiler against the pressure inside! Later improved efficiency used exhaust steam in a feed water heater to warm the incoming water to near boiling. Super heating the steam prior to use in the cylinders made further improvements in efficiency.

At the Hillton Water Plug: We are at Hillton to photograph the arrival of the “Hillton Turn”. They have just dropped today’s arriving traffic on the inner passing track. The engine is on the ‘Y’ connecting track. The fireman is atop the tender to fill it with water while the engineer is walking up to the front end with an oil-can for the monkey motion linkage and lubricators on both sides of the engine.

Caboose track at Yardley: We are at the other side of the roundhouse. – On the left edge is the yardmasters tower under the Hillton big bridge. These 2 tracks are the 13 car long runaround within the yard. The caboose track lies beside the yellow stores building for caboose supplies. Such as lanterns and oil, flashlight batteries, fusses, air brake hoses and gaskets, gloves, etc.

Far side of the Roundhouse

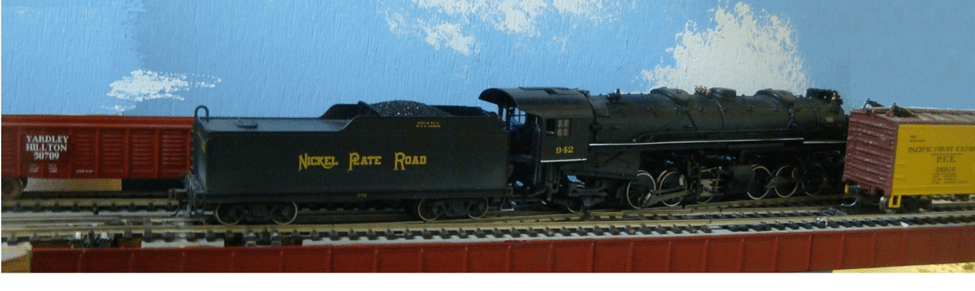

I suppose no story about the Yardley and Hillton would be complete without something about their locomotives. This photo is from a different vantage point. I often try to add weight to get a locomotive to run better or pull more. Or just to personalize them in some regard.

This view from the far side of the roundhouse is taken from across the caboose track (with the caboose stores building removed). The photographer used a small tripod on the yard tracks to support the camera. The light was from an overhead clamp lamp on the room rafters. This illuminates the subject and leaves the background across the operation pit in dark shadow.

The caboose in the foreground has just returned from the chop shop, still needs the name and number. It is a modified Mantua streamliner that has been lengthened by 4 feet and has all three side windows the same size. Locomotive number 983 sports either a Vanderbilt tender or a regular square side model, his choice. In the distance is number 809 with custom decals and a dog house on the tender. (Difficult to see with this light) They were used by the head end brakemen on local runs with engines having a small cab and single fireman seat.

I have wanted a Vanderbilt tender for several years. Finally here is a Model Die Casting Roundhouse kit – a nice short Vanderbilt tender that I modified to pick up electricity from both rails. I have done a little cheating with the graphics here but I had a good time. The Vanderbilt tender graphics was done on plain paper with a home printer (we can print yellow – but not white) and stuck onto the black body. The square side tender road name was removed with photo retouching software for this picture.

Excursion Train on the Yardley & Hillton

This is a rare sight – you don’t see many passenger trains on the Y&H freight handling railroad. Here is a passenger excursion train (note the papered over letter board) leaving the Yardley station. The photographer got this shot with his camera on a tripod standing in the yard.

On top of the steel panel bridge is a passing freight train pulled by the Varney Berkshire with a Vanderbilt tender that I built from a kit in about 1963. The locomotive was sold without a tender for about $48; that was serious money at a point in time when you could get loco with tender kits for less than $20. Those were probably by Model Die Casting, Penn Line, Mantua, Varney, John English and others. The tender is by Kemtron I think, a solid block of hardwood- household baluster stock- you must provide trucks, frame and couplers. Below the steel panel bridge is the Yardley Passenger Station and this view of a leaving excursion train. On the next track is a freight train with another Vanderbilt tender (modified for 2-rail pickup) waiting on the passing siding that will follow as soon as the passenger train clears up. In the yard we see a shortened caboose and a couple cars.

Hillton Turn Illustrated

The ‘Hillton Turn’ (our operational jewel) is a regular – almost every day event on the Yardley and Hillton probably because Hillton has 3 times the traffic capacity of the mainline and some comes from interchange. It is hard to get a picture of this scene because there is no place to set the camera. So while standing on a step ladder in the pit I held the camera (and a small mirror to observe the camera display during the shoot) as far out as I could reach with a sky painted back board (resting on top of the roundhouse to mask my shirt) for a background. The scene was longer than the sky-board so I patched the ends with the MS Paint program to hide the wrong stuff. It turned out that this ‘both sides of the job’ turned out to be a rather long photo.

It looks like the photographer went to the top floor of Hillton’s Hotel Hilton for this unusual photo of the arrival of the Hillton turn. The loco has just cut off his train (gondola) on the inner pass and is backing over the crossover between his cars and those of today’s leaving train (refrigerator). He will back over the wye, top off his water if necessary and connect to the leaving cars, pick up his caboose (and conductor) with the cars of the leaving train and proceed down toward the mainline at Hillton Junction.

Illustrating the operational jewel of the layout — making the Hillton turn.

The preparation for the arrival of the Hillton turn has been done by Hillton’s local switching crew. Here we can see the placement of today’s shipping traffic on the outer passing track. (Inner and outer passing tracks share the bridge to the tunnel). The outbound train is divided into two 4 car cuts spaced over the turnouts of the passing track crossovers, the lead to the industries of WREX, the scrap yard, the travel trailer factory, and the Y connector track. The local switching crew and their short caboose can be seen resting out of the way near the engine house. The local crew will get busy spotting todays arriving traffic as soon as the mainline turn crew leaves town.

Today’s turn train has arrived on the inner pass (with 8 cars) from the mainline connection at Hillton Junction. The mainline engine has cut off and can be seen backing over the connecting track to the wye tail track. He can take water if needed then turn on the tail track and back into the shipping cars on the outer pass shoving the two halves of that train together before leaving and back the train into his caboose to take his conductor with the new shipping cars for return to Yardley or staging via Hilton Junction. The local switcher will spot the arriving cars.

The handling of 16 cars to and from the branch line is a pretty big operation on an 8×11 foot layout. Next the local crew can get busy spotting todays arriving traffic at the involved industries

The original track plan called for a single track into the tunnel, but I felt that if we need a bridge why not make it double track. I am really glad I did that because it enabled this operation which allows the temporary spotting of cars on both sides of the crossover toward the Wherezatgo Tunnel and probably doubles the number of cars that we can handle with this realistic operation. Every layout has an ugly corner and this on the lower level is mine. With a bridge over a roundhouse, an industry under a cliff and Holden stage and yard access tracks. I believe this is less ugly than the wires to a transformer-throttle visible on some layouts. I feel that I should apologize for my elbow in these photos but I was standing on a step ladder holding the camera against the ceiling to get these pictures. This is my effort to get a still photo explanation of using the Hillton wye to turn a locomotive around for the return down the mainline of which I am proud.

Leave a comment