Controls and Operation:

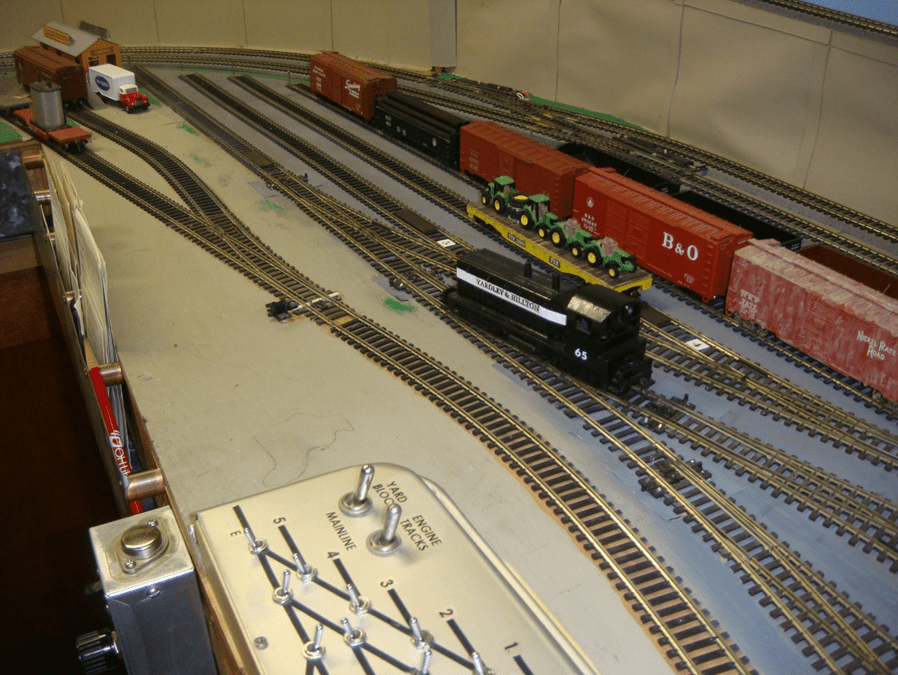

The two best design features I like about operating my classification yard is it allows me to stand or sit right next to the action without having to reach over mainline running trains to tend the yard as with some other layouts. Another thing I like is that my yard has a full train length runaround track. The classification drill lead track is paralleled by the engine service track. The two of these combine to provide for a full train length run around which is an important feature in any yard to be able to get engine or caboose on the other end of a train without fouling the mainline. There is also a short caboose runaround track handy for use by the switcher to attach a caboose to the correct end of some trains.

My classification yard consists of 5 stub ended tracks drilled by an approach track about 13 cars long around a 27 inch radius curve with an electrically operated curved switch at one end with a parallel engine track and adequate length for necessary head room. This allows for all the movements required to handle road engines to or from either east or west bound trains and for the yard switcher to get in and out as needed. The engine facilities are quite compressed, with just 2 short tracks (each – one engine length long) approaching the turntable, which I call arrival and ready tracks. As for the coal and water facilities, there is a coal dock, which straddles one track and serves the other and a nice round water tower.

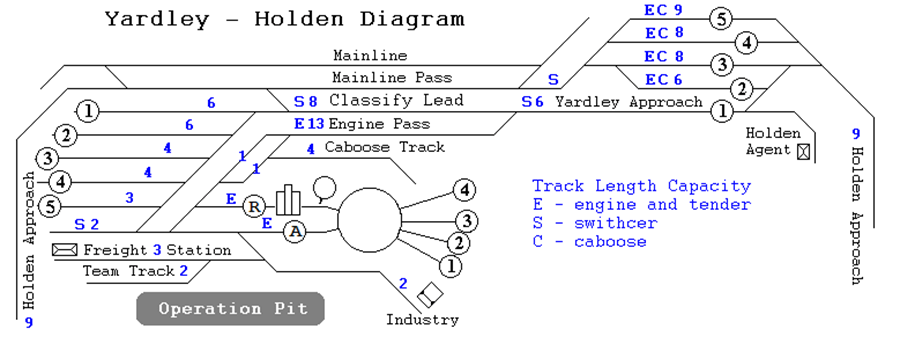

Tracks of the straight-line schematic diagram shown here actually wrap completely around the operation pit. The Holden Approach track of 9-car capacity is really one piece of track 9 cars long. Track car capacity between turnout clearance points is shown in blue print. I have printed 2 of these diagrams and mounted them on the bench framework at Yardley and at Holden for operators’ information.

The roundhouse stall and approach tracks are powered through a 12 – position rotary selector switch. One would only want to run one of these tracks at a time. The turntable bridge track rotates by electric motor that uses the same power as the trains, so the same throttle controls its movement. Rails on the turntable bridge track have automatic polarity control. Track alignment is manual by eye.

The caboose spur track extends off its short runaround track along one side of the round house and under the overhead bridge. I found this little runaround to be handy for when the switcher has to runaround a caboose for attaching to the far end of a train. I had to shorten this spur while building the round house. (Man, those things are big). I was able to get enough length for about 4 cabooses by eliminating a couple stalls in the roundhouse. This seems to be adequate caboose storage after I got into operation. While laying out the turntable and roundhouse stall tracks, I was sure I could accommodate my largest engine, a Berkshire; I probably will never have anything larger. (I later learned that some Berkshires, with a large tender won’t fit the 12 ½ inch table.)

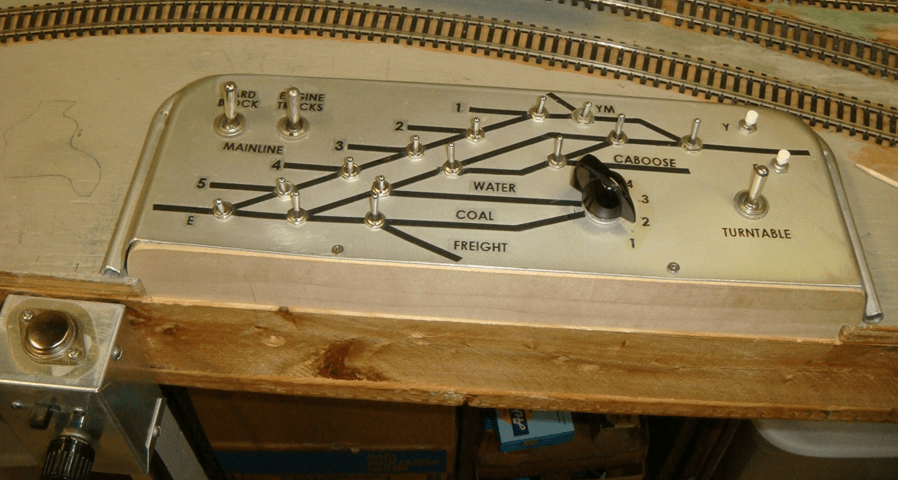

The control panel for Yardley, another one of my aluminum cookie pan panels, has power selection toggles for classification lead, engine tracks and turntable rotation to provide for local or mainline throttle to power each block. Most all the tracks are stub ended and track power is controlled through the turnout points. I used Peco turnouts because I like the way they worked, but I did not cut holes in the plywood for their remote control coils at the time, and then thought it to be too much work to do it all over again. (Procrastination and sorrow endured for over 15 years). Shame on my haste and laziness. Eventually we powered all the yard turnouts with my Grandsons’ help.

The control panel has a double pole double throw center off toggle switches for power selection for both the Classification drill track and Engine terminal track to be powered by either the Yard throttle (local) or a mainline A or B throttle. Operation is usually done with the Yardley hand held throttle, running both the engine facilities and classification chores. This same throttle is used to power the turntable rotation motor. Another toggle switch (DPDT) controls whether power goes to the yard tracks or the table rotation motor. The turntable features automatic bridge track polarity by using a split ring rail and shim stock wipers under the ends of the bridge to carry power to the bridge rails (drawing on page 28).

Along the front edge of the yard table to the left of the control panel can be seen a row of pockets used for car cards (for the cars that are in the yard) of my freight car forwarding system. This system helps me keep track of which car is going where.

About Yardley Industrial tracks:

There is just not much room for industry operations here with just a freight station and team track. This is another place that got gypped on scenery space after the yard tracks were laid. But I don’t care. After all, I was building a classification yard and engine terminal in a tight space, scenery must settle for what is left over. I found that I could get to the freight station and a team track with a switchback move by curving a track around the control panel. The team track has an end ramp, which is fun to use for depicting early piggyback trailer* operations. I remember such a thing in a town not too far from here. Of course the layout is arranged so that a car going from here to the end ramp in Hillton will arrive facing wrong and have to be turned around prior to delivery. A car arriving here at Yardley faced wrong would have to be turned on the turntable.

There is just one other industry in town called The Underhill Fabricating Company. It is tucked behind the roundhouse and under the Hillton Big Bridge. It holds just one car. I was able to access it by sneaking a track alongside the roundhouse, just at the edge of the layout table. I made a two-story paper building here with a loading dock for train cars.

The power source for the towns of both Yardley and Holden is an old Lionel type “T” 100-watt transformer with an assortment of voltage taps which should not be used for speed control with HO. The thing must be 70 years old, but it works well. It is quiet and stays cool. It feeds my homemade transistor throttles through a bridge rectifier. It runs everything in the yard including the turntable motor. Overhead lights for Holden staging tracks are from a separate transformer.

Leave a comment