Maybe the best thing to do with a kit is to use it as a starting point, then go your own way to new detailing heights. Walthers has an HO scale plastic conveyor kit that has some good and some bad points. The bad point is that there are no flared sideboards at the bottom of the tall conveyor to funnel the material into the machine. This design assumes that the second elevator must sit straight in line with the lower one. On the other hand, the nice part of this kit is that there are 3 in the package. By making flared sideboards on the bottom of the tall conveyor I was able to use it at an angle other than straight inline. Here with photos is how I found adaptive uses for this neat little machine as scenery detail.

This design represents two conveyors – a tall one and a low one – of a two chain link cross-bar design the low short one that can take material from a hopper car below the rail (remove a cross tie) and feed it to the tall conveyor. An improvement would be to allow for other than straight inline arrangement of both machines. I made a flared chute to funnel material into the bottom of the tall conveyor from folded paper and glue. The prototype for this machine probably dates from the 1920s or 30s. With foldable flared side boards the lower conveyor could gather material from a dump truck. There are more photos of action with this machine later in the book (page 62) in the background we see the tall grain silos of MGM (Midwest Grain Merchants).

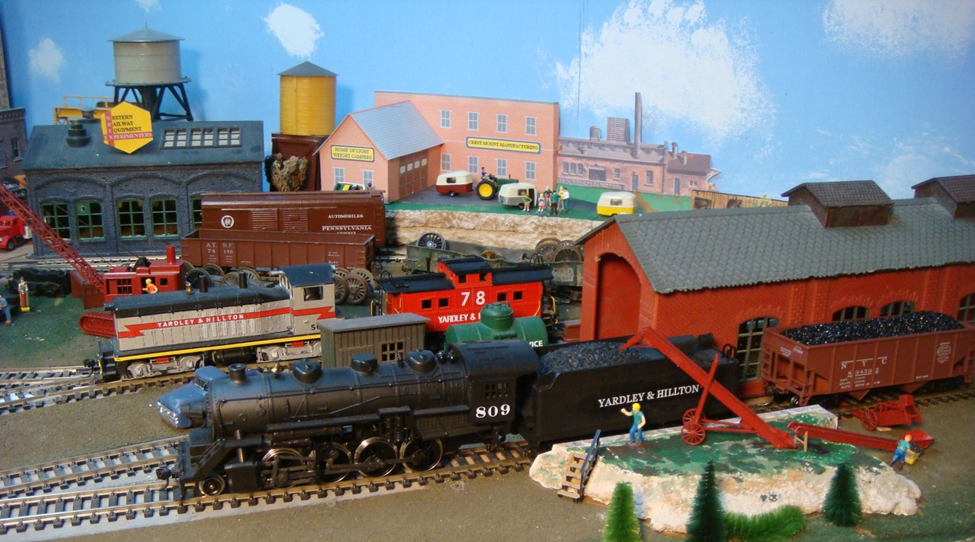

The Yardley and Hillton has a good place to use a conveyor like this at the bulk materials track adjacent to the Mirage Warehouse flat paper industry. But on my layout, getting the camera into position to take this photo was a bit of a trick because the wall of the room is only about a foot away. I tried leaning a mirror against the wall and shooting into it, hoping to reverse the image later with software, the results were disappointing and not worth the effort. However this scene was captured by holding the camera in one hand and a small mirror in the other (to observe the camera’s digital display during the session) then holding them both out at arm’s length with the camera aimed toward my belly. Note my black and gray shirt in the background.

I also found another use for these conveyors, read on:

Using Walthers conveyor to coal a locomotive

This next illustration needs the support of a story about how and why it came into operation. Rumor has that the original coaling tower here at Hillton had been struck by lightning, caught fire and burned to the ground. The railroad did not want to spend the money to build a new one now that diesels were on the horizon. So a cheap alternative (that is important) was worked out. It uses two conveyors to take coal directly from the bottom of a hopper car spotted by the engine house into a road locomotive backed carefully into position. One conveyor alone is not tall enough to reach a locomotive tender. Now the road locomotives can have their coal replenished while the local switcher (now days a diesel) spots the incoming cars.

With Hillton at the end of a branch line, road locomotives are usually turned there on the ‘Y’ track before returning to Yardley via the main line connection at Hillton Junction. Locomotives can take water from the standpipe near the ‘Y’ tail track. Why not use the opportunity to fill them with coal also?

The second elevator has the flared bottom shielding to receive coal at an angle other than straight and the top chute is mounted at a slight angle for discharge into the locomotive tender. This all should work pretty well if you can stand the noise. I am not sure how popular this method of loading coal was for other railroads, but at least the Y&H won’t have to wonder what to do with an old and obsolete coaling tower in a few years.

I will bet that all this machinery rattling and clattering makes a lot of racket when in operation. But it sure beats shoveling coal into a locomotive tender. Remember back in the days of steam locomotives, tractors with hydraulic front-end loaders were hard to find and cranes with clamshell buckets were expensive.

Homemade grain elevator

Back on the farm about 1950 my Grandfather made a conveyor to elevate ear corn into the corn crib from hard wood framing, metal chain link paddles, electric motor, a couple ’V’ belts and pulleys, a couple steel dolly wheels for transport and a large flared tin chute at the bottom to aim at with your shovel. That made shoveling wagonloads of corn into the crib (as high as your head) much easier. There are no photos in existence. The idea worked so well that he later built another elevator from steel (having it welded at a local welding shop) to a much larger scale to elevate square baled hay into the barn. In the winter he would spend countless hours in his shop on projects like this for use around the farm.

Leave a comment