Working with conveyors at Yardley and Holden City Team Tracks

On a large layout large – industries like steel mills and coal mines with train load lots of hopper cars are popular. With a small layout, finding suitable space for active industries takes a little more imagination. Here are a few ideas I have tried on my Yardley and Hillton HO scale room sized model railroad. Using the Walthers number 933-3520 conveyor can work either loading or unloading rail cars or trucks. This machine may have found use in the 1930-1940 time frames. They were powered by electric motors although some probably used gasoline engines. I have found a few opportunities for using the machine in small industrial locations. – read on.

The lower conveyor could have foldable flared side walls for gathering grain or gravel from a dump truck. My flared sides were made from folded paper glued to the bottom side of the lower conveyor. The lower conveyor passes the material to the taller conveyor.

Using the conveyor in two places; the first is at the freight station team track at Yardley with a couple box cars and part of the classification yard in the background. With a little more imagination you may find another opportunity to utilize this handy light industry machine.

While making action scenes for the camera I have learned that short two axel dump trucks are easier to fit into these scenes than the larger modern day semi-truck style ‘coal buckets’. This conveyor is being used to ship natural gravel.

Here is another view of how this bit of layout detail fodder can work out. The scene seemed difficult to arrange for a suitable view for the camera. The gravel load is a shaped piece of Styrofoam painted on top with a liberal coat of white glue and dipped into a container of Woodland Scenic gravel picking-up about one granule thick. The dump truck with the elevated bed and tailgate partially opened regulates the speed of unloading, the supervisor in the blue shirt looking on, and the truck driver in his black jacket and is that a car inspector climbing on the hopper car? Adding these details can fill winter time hours with enjoyable hands on fun. On the layout both these views are contained in about one square foot of real estate, less than a foot apart.

Holden Agent’s Headache

It is Monday morning and the freight agent at Holden City is greeted with a problem!

Last week the conveyor operation finished shipping gravel and parked their machinery to just across the spur track in front of the Freight office building. Now it is Monday morning, the local freight train crew left a box car of lcl (less than car load) packages overnight, for delivery by Railway Express Agency. That business was probably a predecessor to United Parcel Service that we see today. It appears that REA has arrived and that conveyor machinery is blocking access to the box car! The freight agent has been on the phone getting the gravel boys to move their machinery out of the way ASAP. Usually dumb problems have simple solutions.

Here I tried to fool the camera. This photo has a false background of blue sky to block the scenery behind. When I painted the sky board for the layout I made an extra small piece about a foot square, I thought that the board painted blue sky blue could blind the camera to the existing background, but this is not the best way to show that trick. There are better views elsewhere.

Farm Utility Trailer

Farming introduces one to all kinds of ‘make do with what you’ve got’ situations. I recall the two wheeled trailer we had on the farm where I was raised in the early 1950s. It was home made of wood with steel and heavy oak framing on a front axle, springs, wheels and tires from an old automobile. Atop this was a homemade wood box with provision for removable wooden racks for hauling a cow. There was a hinged drop down tail gate. We used it to go to mill for cattle feed or to haul a ton of coal for the house furnace. It was pulled by a tractor or the family automobile – stay under 40 miles per hour.

Some other farmers had used the back end of a pick-up truck and some welded steel frame work for a hitch. It seemed to me that they would be heavier with the cast iron axel and differential housing – but hauled no more material. None of these rigs had brakes.

I thought I would try making a scene to illustrate recollections from my youth. Here is another scene I had fun with at the feed mill on the Y&H. The Leake Oil billboard – (by modifying their advertisement from the yellow pages), the master mix sign was done with the computer paint program, hand painted figures, the burlap feed sacks, hand painted sky board back drop and the last half of a pickup truck with a bent wire hitch.

Finishing details such as these and making a setting for the camera can provide cheap hands on entertainment for the hobbyist for many years.

Screw Auger Conveyor

Furthering our study of conveyors

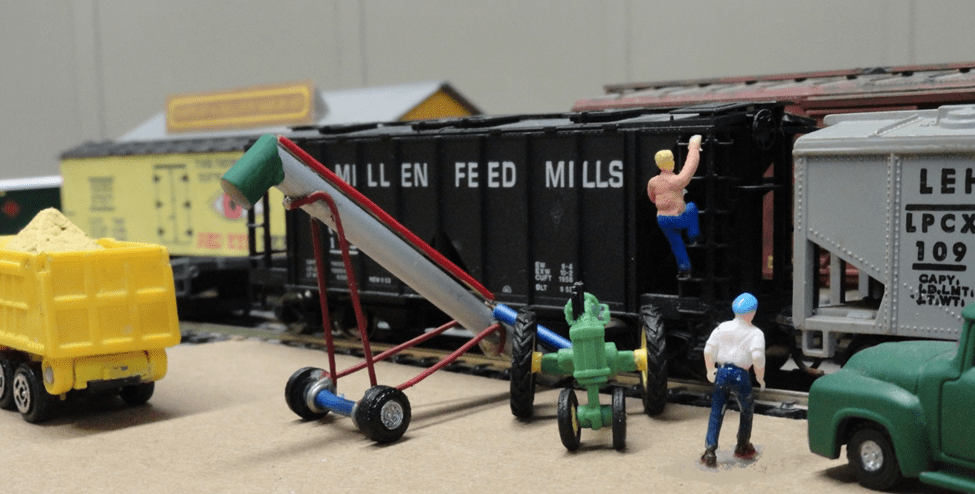

Modern methods use a different type of conveyor to move material like feed grains. Our local feed mill works from the team track and uses a screw type auger to handle grain. It is probably over 24 feet long. I wanted to show how this was used recently near home so I tried to scratch build a scene to illustrate their procedure. They use a red farm tractor with a rotating power-take-off shaft and universal joints to propel the machine. There is a depression between two ties on the spur track where the auger fits above the rail and beneath a bay of the railroad hopper car. They carefully line that hole (it could be full of water after a rain) with sheet plastic and plywood scraps to control spillage. The machine is light weight and relatively easy to move around which has to happen for the next bay of the hopper car which must be moved over the hole. They use a log chain and another truck to move the car. This can be a tough job in slippery, freezing weather. This is truly advanced over older methods. There is a work-man on top of the hopper car and another on the side of the truck to signal the driver when to advance to even the load.

The tank type truck on the left has a self-unloading system consisting of 3 hydraulically powered screw augers, a bottom one below the load, a vertical one seen on the rear, and a movable horizontal one out of view on the far side of the truck. This machine can also be used to move grain the opposite direction – to load a covered hopper with grain or meal. The men are careful and neat, there is not even a shovel-full of grain lost to spillage.

Scratch building a scene to replicate the principals of the prototype.

The screw auger conveyor was scratch built using plastic tubing, wheels from an HO scale automobile with a longer tube for an axel and both insulated and bare wire plus a little paint. The load in the truck is a shaped block of Styrofoam painted with acrylic paint. The workman climbing down off the car has just closed the lids prior to car movement. The man in the white shirt will disconnect the power take off drive shaft for movement of the machinery.

This close photo was taken on the team track at Yardley and shows how my work will never win craftsmanship contests. My intention was to illustrate the concept – not museum quality details. Remember my photos were taken on an operational model railroad layout, not a diorama. The pavement in this photo is the cardboard back of a tablet laid at the edge of the layout temporarily enlarging the work space for the conveyor and the camera. The refrigerator car in the distant soft focus has sides home drawn and printed with the computer, the black hopper is by Bowser, The gray hopper is HO scale by Marx.

I wanted to make a license plate for the trucks naked rear frame saying something like HO-187 but I was not able to get things small enough. Maybe I should have made a virtual plate with software in the computer and not on the model. I now think I should have weathered the rear end of the truck a bit; it is just too clean for the back of a dump truck. Maybe I was too quick to get the camera.

Mirage Warehouse and the Bulk material track

The Mirage Warehouse is a homemade paper flat mounted on angle brackets right at the edge of the table work. Those brackets are hidden by the tall buildings of Holden City. Later I learned that those brackets are unnecessary, the warehouse could be pasted directly onto the back of tall building flats. The bulk material track at Hillton’s Mirage Warehouse was a good idea to provide an additional destination on the layout for hopper cars. This is like gaining a second industry within the original space of one. This scene was taken at Hillton on the dual purpose / bulk material track next to the Mirage Warehouse. This track can be used either for overflow box cars at the warehouse or hopper cars unloading bulk material to a dump truck.

I have always liked this shot of a half unloaded car of gravel and a half loaded truck to haul it away. The photographer had to be a bit of a contortionist to get this picture. The distance between the warehouse and the wall of the train room is about 14 inches. I don’t have the courage to scatter gravel up the slope of the conveyor. Note the truck driver in his black jacket is usually found near the truck in my scenes.

Leave a comment