I was remembering an interesting story found in a major train magazine in the early 1990s, very elegantly written describing the happenings of a young engine hostler on the last day of his employment with the B&O. The story probably took place in the 1930s or before. I felt inspired to set-up scenes on my layout for the photographer to illustrate this sadly humorous event:

The story took place at the engine servicing facility on a small branch of the B&O south of Akron. This was a night job and the young man usually worked alone. His job was to prepare the few road engines for tomorrow’s work. This included banking the fire, add oil to the lubricator, add coal and water to the tender etc. to a few road locomotives. These activities required movement of the locomotives to the respective dispensing facilities. The chores required frequent climbing up and down locomotive ladders, checking the level in the sand dome, walking to the other end to throw a track switch etc. Over the summer he learned a few short-cuts to save a bit of work. Full appreciation of this event requires an understanding of how a steam locomotive works and its two brake systems – the locomotive brake and train brakes. He learned that with the throttle cracked just a bit, he could move the loco forward at a brisk walking pace – throw the valve gear to reverse – then using the momentum of the loco’s movement – jump off the engine – throw the track switch as the loco rolled past him – then climb aboard the engine foot board as the loco direction changed – grab the train line air brake valve and dump the air, thus stopping the engine so he could save a bit of time and effort. However thistime he was surprised to discover the train line valve was already open! No air- no brakes, and he rode the locomotive foot board as the tender entered the turntable pit! When an operator messed- up, we reminded him of the ‘last day on the B&O’!

Engine Hostler Chores

Let’s talk about what an engine hostler does. Maybe we can setup some scenes on the layout at the roundhouse for the camera. There are lots of general chores around the roundhouse. Clean up the ash pit with a shovel and a low side gondola, tending to locomotives such as preparing them for their next trip, greasing the valve linkage on both sides, fill lubricators with steam oil, top off sand for traction, fill the tender with coal and water, lubricate the stoker if it has one, check lights, etc.

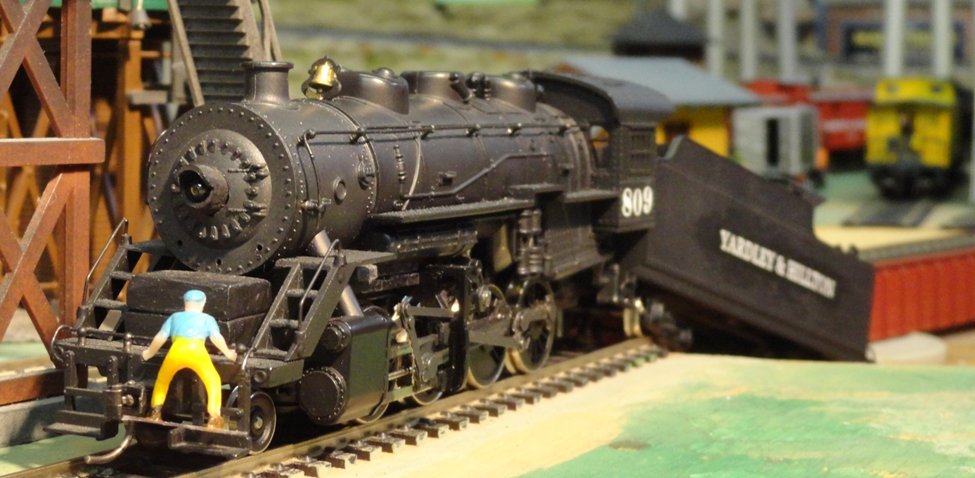

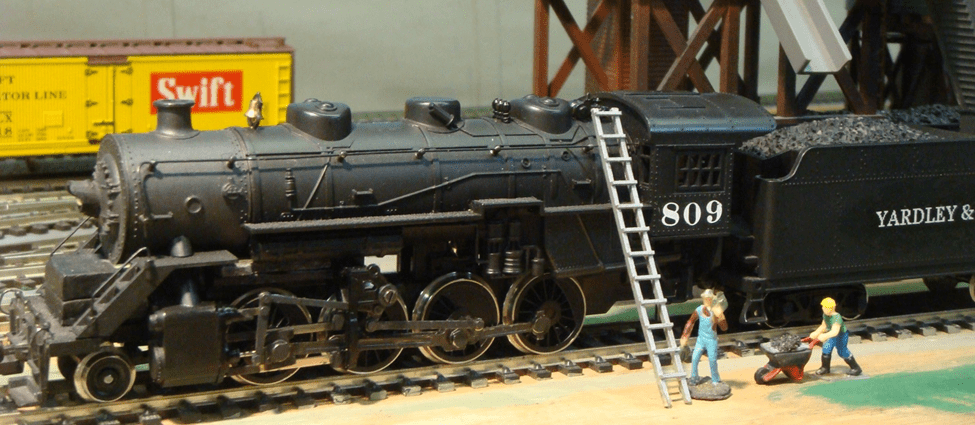

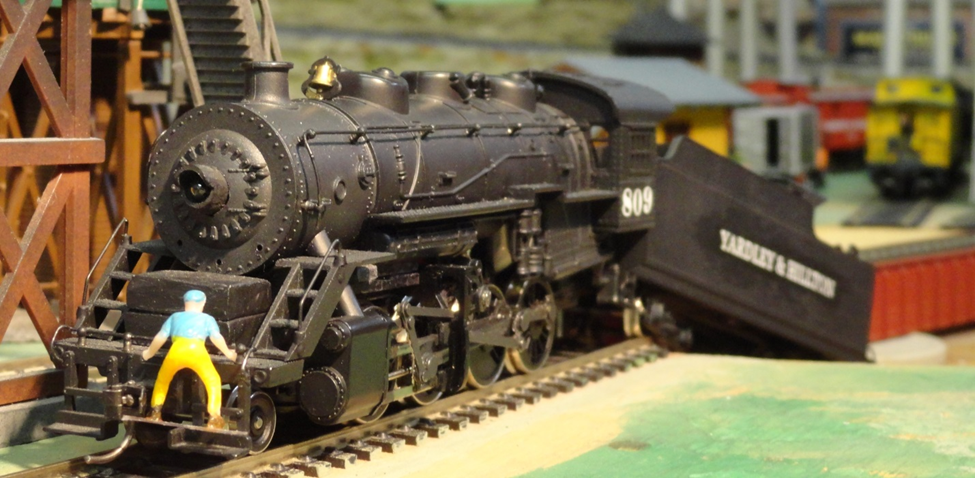

It is good to have a ladder to get to the top of a locomotive. This one is a heavy 4-8-2 by Bachmann Spectrum with custom decals. It is nicer still if the railroad has a sand tower for re-filling the sand dome. It is easy to understand how short-cuts are found on the job.

It is a pretty tough job using a bucket or a gunny sack to fill a locomotive sand dome. This loco a 2-8-0 by IHC has extra weight on the pilot deck, above the first driver (sheet lead) and inside the roof of the cab, a modified smaller head light and a dog house on the tender for the head end brakeman on locos with a small cab.

Some of the hostler’s chores become mundane like walking to the other end to turn a track switch, and walking back again and you have to climb back up into the cab to move the machine. You had better have good legs for a job like this.

Don’t lose your water.

Here is an overhead view of this real life happening from the B&O replicated on the Y&H. The water connection between the locomotive and tender is broken!

Understanding Murphy’s Law

Murphy’s Law says that if anything can go wrong – it probably will. There is another axiom that says nothing is as simple as first assumed. The wreck boys needed another loco to get #809’s tender out of the pit. That is because the water connection between the locomotive and tender has broken so we can’t put water in the boiler, we had to let the fire go out, now the engine can’t move itself. We had to get the silver colored switcher #56 to help out by bringing the wreck crane from Hillton and by the time it got here #809’s steam pressure was so low that it couldn’t even blow its whistle. The crew used wood blocks as cribbing under the outriggers of the crane, but then was only able to move just a foot or two before letting the lift down, move the crane a couple feet, reset the blocking under the outriggers, get a new hitch and then repeat the process to move both the WREX #69 yellow switcher with #809 and the Y&H switcher with the wreck train and crane. The photographer was not able to get a close shot of the details of the outrigger. This is how a dozen men can lose an entire day’s time. Who would believe that it could take three train crews plus the wreck crew for this job? Diesels come to the rescue.

This post of stories consumed over 15 hours of my retired time, with mixed memories, and a bit of imagination. While this story may have some spiced-up details, and a bit of sarcasm, I really enjoyed doing it.

Leave a comment