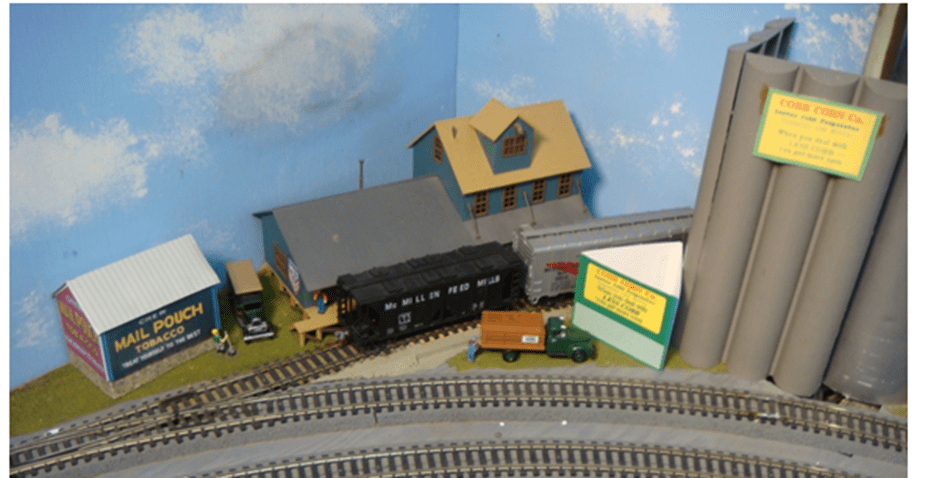

This is an overall photo of the original location of the Cobb Corn & Grist Mill Co. in a corner of the layout at Hillton Junction as it had existed for several years. I always had a grist mill for the grinding of cattle feed and other supporting scenery there. Such as the grain storage silos on the right that hides a gas pipe, a 3-sided billboard and of course one of my Mail Pouch barns which became a virtual storage shed for a virtual tractor. Local harvest time lasted a month – marketing time (Pillsbury baking flour) lasted all year-long.

Often there was a busy scene to be found here for traffic on the railroad. Such as handling cattle feed in burlap sacks or loading grain into boxcars about 1950. I used the computer graphics program to make modifications to some old photos of the layout for a new story. That experiment is shown on the next page. (The Mail Pouch Barn on this post is REAL).

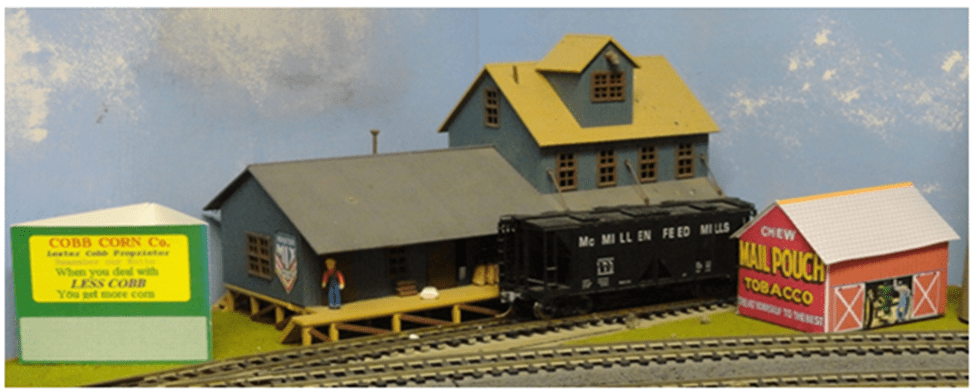

Virtual Tractor Shed

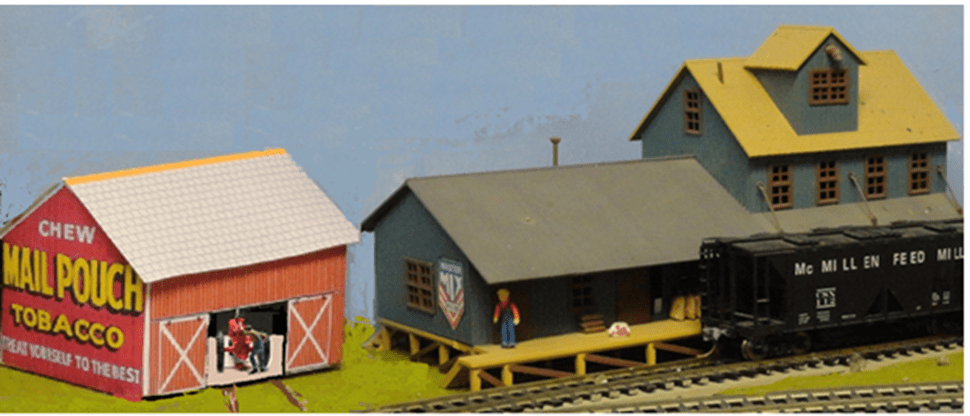

By using Microsoft Paint graphics program I opened the doors on one of my Mail Pouch barns and placed a virtual green tractor inside – I had some sizing and perspective troubles. The tractor shed was too close to mainline tracks and I felt that it was too small. I returned to this concept after we moved, there was not much else to do in my retirement living home. I guess the fun of the layout is within the computer now days. The layout was gone but these photos were in my computer, I just had to engage my imagination and bring them to a different story. (The virtual red barn is too close to the mainline track).

After resting my brain for days or months, this final scene has a larger and relocated barn with a red tractor inside and now room for a driveway path into the barn. 11-15-19.

I was having fun with the layout by using pictures two years after the layout was gone.

On this post, only the first and third images are genuine photographs. The bottom two photos have been enhanced with graphic software to tell different story.

Before the Coal dock fire

This late story uses the same painted brown paper scheme at Hillton to hide good working tracks for a different story— back when Hillton had a coal dock for steam locomotives. I found myself doing things I never would have thought about in all my years (about 30) with this layout.

As you may recall from previous mention (page 12) the coal dock at Hillton had been struck by lightning, caught fire and burned to the ground. This story attempts to tell how the original coal dock looked before the fire. I like to tell stories with the support of photographs. That means that I will have to take photos of something that never existed! So I found myself removing some scenery that is too late for the story time frame – I need to show action before the fire. It became apparent that the tail track used to be longer and contained a turnout for the switch-back move to put loaded coal hoppers on the dump track under the dock.

The time frame was before the scrap yard and the travel trailer factory, so I removed them for the cameraman. This style coal dock had the dump track contained under the facility. Putting a hopper on that track required the switch back move from the longer ‘Y’ tail track.

Color print film was rare when I was in high school. I dislike black and white photos now that color is so readily available (even on your phone), but in this case it may help set the scene of long ago when the industries of Hillton were served by steam locomotives.

I believe that Hillton originally had a steam switcher or sometimes a short saddle tanker which is nice to use in tight quarters, there was an 0-8-0 with a slope back tender that came from the PRR. After the coal dock fire the railroad used a diesel switcher to service Hillton.

It was difficult getting a good picture for this story; it seemed that the coal dock wanted center stage in all the photos, those things are really big for a small layout.

The Hillton assigned switcher an 0-4-0T is spotting coal cars under the dock on the dump track accessed by a switch back move from the longer tail track. Apparently after the fire destroyed the coal dock the railroad eliminated the dump track and its track switch and shortened the tail track. The site of the dock became a scrap-salvage operation which is more interesting to look at than the coal dock. Is this the end of the line? My imagination is empty; I have no more ideas for having cheap fun by setting up scenes to share on my Yardley and Hilllton HO scale layout. (I had a heart attack Dec. 2016)

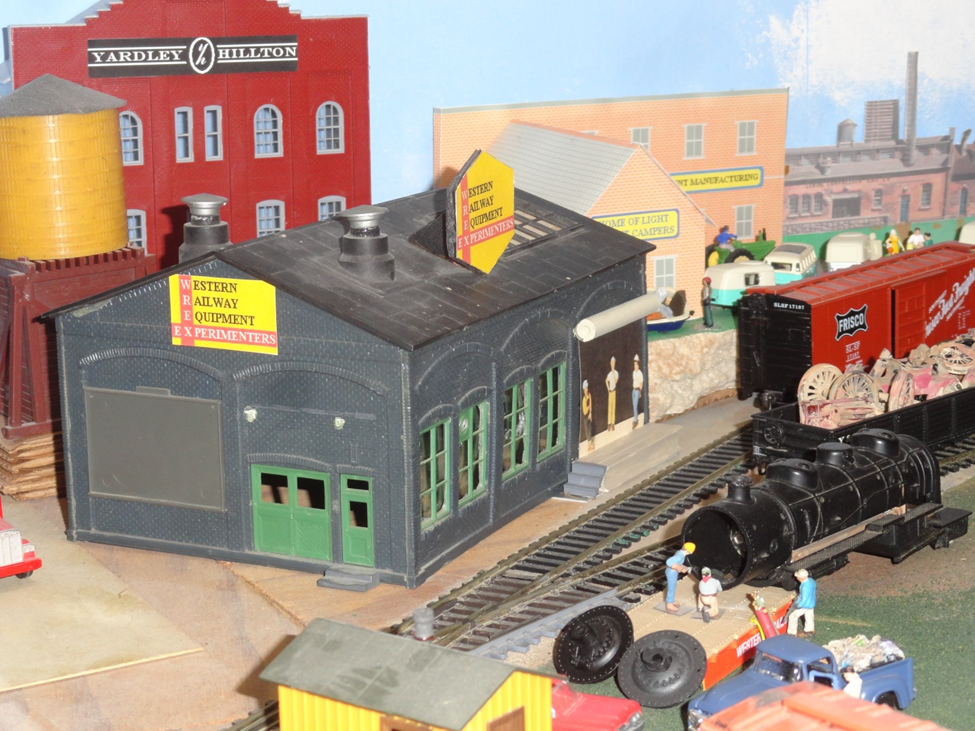

WREX additional work: (re-visiting an old industry)

This late idea was photographed in the spring of 2016 and written about in fall of 2017.

I thought if the Western Railway Equipment eXperimenters had a back door and a loading dock the company could do extra work in addition to railroad work when things get slow. This is a way to get new traffic from an old industry. The structure’s large panel with windows is located between the steel frame work (underneath the bricks) and that panel could be removed without damaging the strength of the building, and then that opening could be closed with a large overhead roll-up door as sometimes seen with modern buildings. This would allow us to see more action inside the building. The housing for the rolled-up door was made from a plastic drinking straw for the roll mounted high and a small dock at ground level to serve rail cars. Both are fastened to the raised brick surface which stands about 1/16 inch proud of the brick wall. This leaves a small slot for mounting a photo of activities seen inside. I was attempting a new spin on an old idea. Those 3 men standing in the door-way at the dock look familiar.

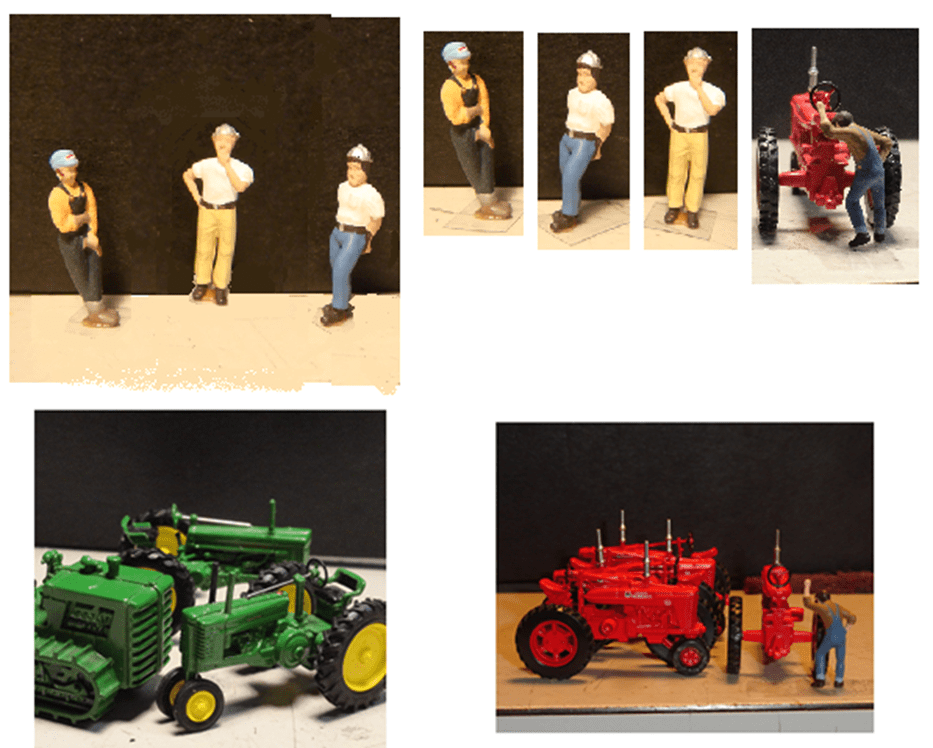

The overhead roll-up door housing is fastened to the raised brick frame as is the scratch built dock floor below. The brick wall has not been cut out so the building structure is not damaged with my experiment. This provides a small slot to hold a paper photo insert loosely in the space which can be changed to suit another business. This changeable photo insert is an idea to allow for occasional changing of the vehicles or products built inside. Most probably vehicles other than railcars. That is how these factory work-men could stay busy during slow railroad times. I thought about other tractor manufacturers contracting with WREX for assembling tractors from previously sent parts. It is apparent that both Farmall and John Deere have had work done here. Parts could arrive in box cars and assembled tractors could be shipped out on flat cars. This nearly unbelievable idea is how a small local business can get into big time shipping operations on this small railroad. And this way we can get a bit more mileage from an old industry.

Here behind our building we see the head office building of the Yardley and Hillton RR. In the left background of the photo on the next page we see the bulldozer factory with production enhanced by mirrors, the newly modified Western Railway Equipment eXperimenters shop, and a bit of the travel trailer factory. From this side of the spur tracks we see an old steam locomotive under the scrapper’s torch, a loaded gondola of scrap, a pickup truck load of scrap and our Conrail caboose office minus its undercarriage showing serious signs of rusting along the riveted seams done with brushed paint. Now we should try closer views:

We can see that both International Harvester and John Deere have had some final assembly work done here at WREX. This may be a hard to believe scheme, but when a desparate modeler wants more variety in his rail shipping, ideas like this may happen. I did not want to remove the WREX sign from atop the building because I had worked quite diligently making it with the computer. Due to its 6 sides – it is not the first thing you do with my level of computer graphic software (Windows Paint program). It has been mounted on the sloping roof with black foam core and I think Walthers Goo if my memory is correct. I had done the art graphics of the sign and glued it to the foamcore backing so long ago that I can’t remember just how it was done.

In the direct foreground is the Conrail caboose ‘office’ minus its running gear mounted on concrete footings with a resting bench at the right end, a pickup truck with a load of scrap iron under the crane, an old steam engine boiler being cut up for scrap by the workmen with an acetylene torch and a gondola load of scrap. In the background is the bulldozer factory with a flat car load of dozers, our WREX equipment structure, the head office building of the Y&H RR, and the edge of the travel trailer factory behind the Frisco box car.

Here in the scene below we see across the spur tracks from the scrap yard looking into the opened factory door with tractor production evident. The open roll-up door covers an opening that measures 12 scale feet high by 15 wide. I wonder if this is too large for a roll-up door. Somehow I have never been as happy with these photos as the ones at Slims freight forwarding warehouse done at Hillton years ago. I wonder if I need to get the camera closer.

These are red Farmall tractors like the one that I grew up with. The man on the right in the doorway (hardly visible in this view) is about to climb aboard to move one of the tractors, probably one of several to be loaded onto a flat car for shipment. The loading dock is painted Plastruct girder beam material; at the left end are stair steps by Central Valley.

The photos of these tractors were staged on the work bench under the good light of the bench lamp with black foam-core as a background, photographed, resized with computer software, printed and slipped onto the side of the building below the roll-up door. I was trying to cheat the system of believable photography.

The above photo – while it looks good – I feel that the tractor is oversize for the location and should not be used. I guess I was still learning and this view, by being poorly proportioned caused me to make another photo. With more properly sized back ground stuff it could look like the inside of a factory with lots of production evident. I seem to be having sizing and perspective problems with my ideas. Perhaps I went about this project wrong-headed.

I attempted another photo session with green tractors in a closer view probably in a show room setting, which maybe the wrong idea for the location. This is still a lot of work with my entry level graphics software.

I think if we would make pavement up to rail-top level and make a driveway, this dock could also serve highway trucks? Maybe that is a project for the future.

I noticed that the floor level is not the same for the front (left) view and side (dock) level, but I don’t let that bother me. Actually the building’s only large door was too small for vehicles.

It seems that we should make a scene that is taller than it is wide to have the proper perspective in the open roll-up door. All of my recent shots of green tractors seem wrong. In reality I just ran out of time with this project. Still I was having fun with my hobby on little money.

The 6 pages here from my book, with a good camera, the story and photos were started before I left the layout, then finished after I got settled into new surroundings with my computer but no layout. I would never try this method again, it is not worth the effort. We moved to assisted living.

This last chapter is to show my latest ideas to get a bit more life out of an old industry documented after the abandonment of the layout.

I want to stress and show with photos how important size and perspective is when mixing previous photos and real structures in the story and how difficult that is to achieve after the layout is gone but the computer and author remain. Ray Lora Fall 2017.

Here are shots of photo work ups for this story – the tractors and figures are 1/87 scale.

Leave a comment