Prior to building the 8×11 foot layout in my basement, I constructed a freestanding enhancement of Chuck Yungkruth’s Gum Stump and Snow Shoe track plan that was 1 x 7 1/2 feet. This Yardley and Hillton was later scrapped so the turnouts could be used on the big layout. The following two photos are among the only photographs found of this switching shelf.

(Version 1. A freestanding enhancement of Chuck Yungkruth’s Gum Stump and Snow Shoe)

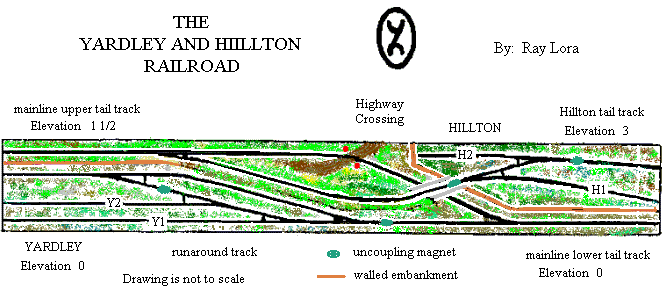

Critical dimensions if built using snap track switches in HO scale:

1- Overall length = 7 feet 6 inches.

2. Overall width = 11 inches.

3- Overall height (including buildings at Hillton and 4 in. frame) -11 inches

4- Vertical clearance under the bridge is 3 inches, permitting 4 percent grade

5- The mainline tail tracks must extend 21 inches beyond the switch points,

to allow trains of a short engine, two 40-foot cars, and a bobber caboose.

6- The tail tracks at both Hillton and Yardley should measure 13 inches

past the points, providing a capacity of an engine and one car.

7- The length of Hillton #1 track is 22 inches from frog to end.

8- The length of Hillton #2 track should be at least 15 inches.

9- The run-around track measures 25 inches between the frogs, which will

clear a cut of three cars easily. There are 6 right hand turnouts and 2 left hand.

The capacity of Hillton #1 track is three cars, access is very direct, allowing one to send or receive loads or empties or both with the same trip, which is quite efficient. The capacity of Hillton #2 track is two cars. However, the arrangement and length of the approach track is such that one can only send or receive cars, but not both on the same trip. This makes for some very interesting switching operation.

The capacity of the Yardley #2 track is three cars, while Yardley #1 track holds five cars. This track also serves as a fiddle interchange and general-purpose utility track.

There is only one operational rule to observe; we must have a caboose on the end of the train opposite from the engine, with all of the cars of the train in between while on the mainline. This allows for the caboose to whistle the highway crossing, (There are no one-eyed-brakemen on this railroad)!!!

With the use of a good imagination we can allow the buildings on the Y&H to represent different industries at different times. For example a good busy chore is to pick up a refrigerator car from interchange from Y1 track, this car must be left on Y2 for icing, then ~ taken to H1 for loading with fresh meat, then it must be taken down to Yardley for runaround (and more ice if in the hot summertime) in preparation for delivery to H2 supplier. Finally of course it will have to be returned to interchange. Meanwhile the crew must take care of other busy railroad traffic.

Also fun is to have five loaded hopper cars at Hillton (mining town) and five empty hoppers at Yardley. Then we exchange empties for loads, preparing a unit train for interchange. This requires that the engine and crew make four round trips to Hillton.

Operation here can be fun with the use of colored tabs laid on top of the cars to aid in identifying which car goes where. Spotting locations can have assigned colors, then move the cars to the proper colored spot as indicated by the tab on each car. After all the cars are properly spotted, change the tabs to different cars and you are ready for another operating session. The layout snap track turnouts were controlled by Atlas switches mounted on the front fascia.

Above is a two-piece version of the layout I would like to build someday. The buildings at Hillton could be low relief flats. The layout would have the blue-sky boards permanently attached to the frame. For transportation, the right half could separate and turn upside-down and fasten to the left half making a closed box about 1x1x4 feet. For operation both halves could connect to each other in the middle; held with suitcase latches, rest on a table, and be operational in a few minutes. There would be room enough for power supply and/or battery under the scenery in the right end.

Here is my attempt at a 3 dimensional drawing for the layout to be a bit more portable for easier transportation. The bottom side of both halves could be neatly closed. For operation the layout could be supported on an 8 foot folding table. The power supply or rechargeable battery could be mounted under the scenery at the right end. The whole layout won’t use much power even with a sound locomotive. A modified (db9) cable could connect the track and turnout power controls for the other half of the table below the scenery for operation. The turnout control buttons could be mounted and recessed on the front fascia. The rolling stock and power cord extension for the layout could be carried in a separate box. This layout was scrapped and the turnouts used at Holden Staging yard during construction of the room sized Yardley and Hillton layout. RLL

Leave a comment